We carry parts for virtually all major manufacturers, including Liquid Controls, Total Control Systems, Scully, Blackmer, Marshall Excelsior, Betts lighting, MidCom and more. Please call to discuss your specific situation and needs.

Serving All of New England | Based in Saco, Maine

12 Mill Brook Rd

Saco, ME 04072

- Mon - Fri

- -

- Sat - Sun

- Closed

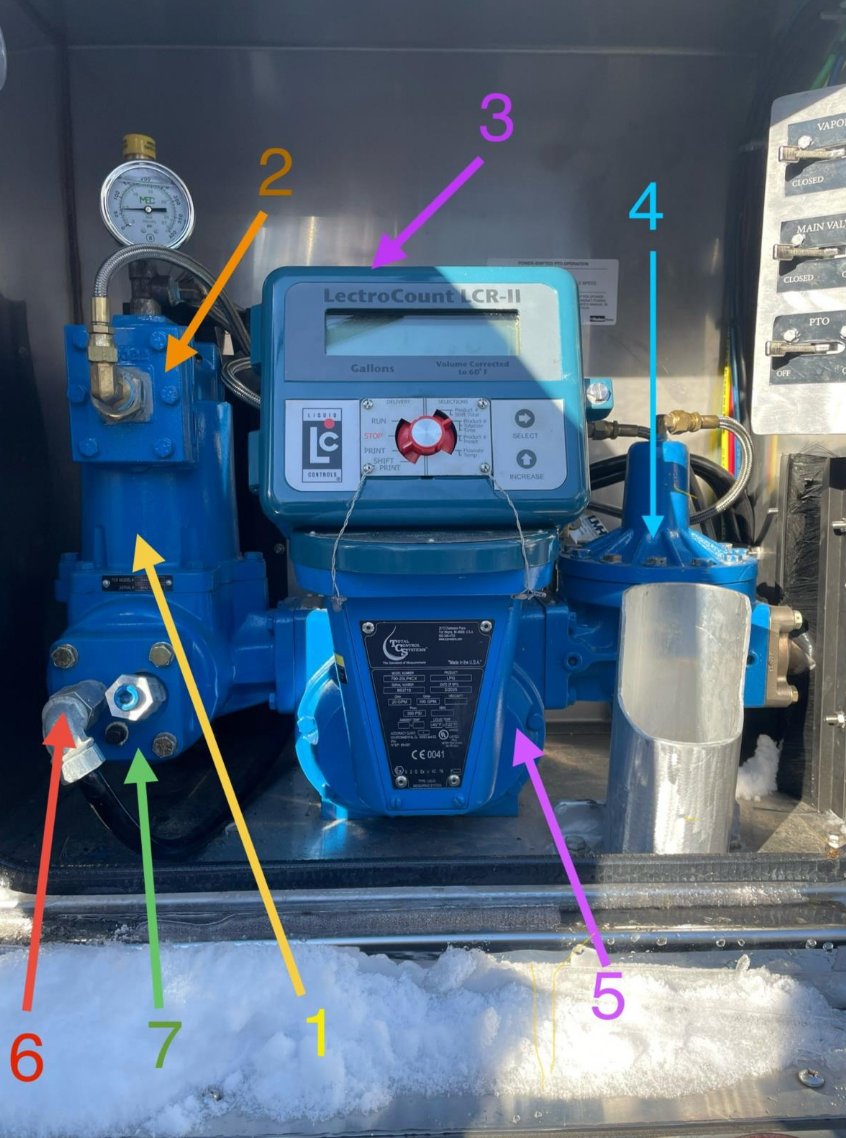

This is an example of a Total Control Systems (TCS) propane meter, with an LCR2 register head mounted on it. The bottom portion is the meter itself, the top is the register head.

Bear in mind that you can mount an LCR2 register head, an LCR IQ, or a Mid-Com E-count register head on a TCS or an LC (Liquid Controls) meter. TCS also makes a register head, the TCS 3000.

These are the parts you will see on virtually every TCS and LC oil and propane positive displacement flow meter in New England. Some parts will vary, but essentially every meter will have these components: an air eliminator tower (mechanical or optic), a measuring unit in the middle, and a preset valve (E7 or diaphragm housing).

TCS and LC meters will have the same basic components.

- Air Eliminator Tower — allows vapor to escape back into the tank so it’s not being delivered to the customer.

- Valve plate cover — there are two, one on each side. They each have a valve plate and a gasket behind them. They are the top portion of the air eliminator tower, and control the vapor flow back into the tank.

- Register Head — can be an LCR2, as shown, or an LCR IQ, Mid Com E-Count, or a Neptune E4000. They will all sit on an LCR meter. This is the “brains” of the system.

- Diaphragm Housing — also called a double block diaphragm. This is the preset valve. Your meter may have a different valve here, called an E7 valve. This valve also controls the flow at the end of a preset delivery, slowing down the flow so the meter can hit the preset accurately.

- Measuring Unit — this is the central part of the meter. It is what turns to count the gallons, turning a pulser gear behind the data plate, which in turn converts the mechanical signal to an electrical count.

- Temperature Probe — this is a thin probe inserted into a well in the strainer cover. It measures the temperature of the product as it flows through the meter so the register head can make accurate calculations for states that require temperature compensation.

- Strainer cover — behind this is the screen that ensures no contaminants go through the hose. This is the bottom portion of the air eliminator tower.

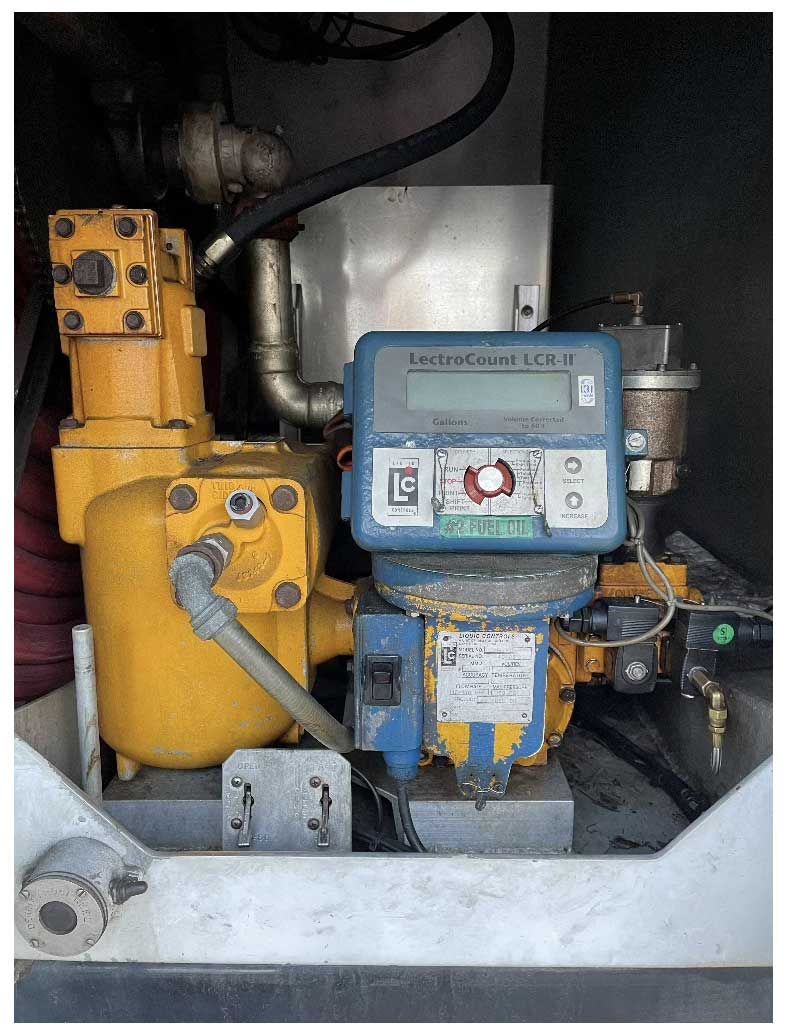

Here are a couple more examples of an LC meter, but with an optical air eliminator tower and an LCR IQ register head. Notice they still have the three main components, air eliminator tower, measuring unit, and preset valve. The air eliminator on these is electrical/optic instead of mechanical.

Below is a distillate fuel meter with an E7 preset valve, instead of the diaphragm housing.

The register head can be physically separated from the meter by the use of a Pod Pulser, which takes the place of the gear train on the measuring unit. In the top picture on the right, you can see the blue pod pulser on the front of the measuring unit. The register head can then be placed anywhere, and a cable runs from the pod to the head. The bottom picture is a TCS meter where the air eliminator tower and the diaphragm/preset valve have swapped sides, and a pod pulser is being used on the measuring unit so the register head can be mounted remotely.